GENERAL

Tranny Tube: Protecting & Cooling Your Transmission

A tranny tube, also known as a transmission tube, is a vital component in a vehicle’s transmission system. It serves as a passageway for transmission fluid, which is essential for lubricating moving parts, reducing heat, and maintaining the proper operation of the transmission. Typically made of metal or durable composites, the tranny tube also houses the dipstick in many automatic vehicles, allowing for fluid level checks.

Beyond fluid transport, the tranny tube acts as a protective barrier, preventing contaminants like dirt and debris from entering the transmission system. Its role, though often overlooked, is critical to ensuring long-term transmission efficiency and durability.

Understanding the Transmission System

The transmission is an important part of any car that transfers the power of the engine to the wheels. It alters gear ratios according to the subject of driving conditions keeping the positive driving, interior fuel utilization, and fuel performance.

Automatic transmission works on fluid pressure (transmission fluid) to run the gears and inner parts. You must ensure that you have proper fluid flow and temperature, and most of these components, such as a tranny tube, are there to make sure that the system runs well and is free of all the unwanted substances.

Primary Functions of the Transmission Tube

1. Fluid Transport and Circulation

The tranny tube has the main role of carrying the transmission fluid in the system. The transmission fluid is lubricated, cooled, and pressurized in different channels, paths, and other existences. The tube also helps in the infiltration of this fluid to the required parts of a vehicle at the right volume and pressure.

2. Cooling the Transmission System

There is a lot of heat produced by automatic transmissions through friction as well as fluid dynamics. The tranny tube works in directing the fluid to transmission coolers, which could be mounted on the radiator or external to it, hence regulating temperature. The result of overheating could be early wear and a reduction of performance, as well as whole transmission failure. The tube comes in handy in enhancing effective cooling of the fluid by forcing hot fluid out of the transmission and injecting cooled fluid.

3. Lubrication and Component Protection

The transmission systems are complex constructions of gears, valves and clutches. The use of a tranny tube is important in terms of supplying lubrication fluid, thereby limiting metal-on-metal contact and wear. Regular lubricating will eliminate breakdowns and improve the life of the internal parts.

4. Shield Against Contaminants

Besides transferring fluids, the tranny tube acts as a shield or prevent the transmission fluid system from any dirt, moisture, and other debris. Communication of such contaminants may cause reduced hydraulic pressure, corrosion of metal parts, and expensive repair works. The integrity of the system is hidden behind a well-sealed and maintained tranny tube.

TRENDING: The Surprising Benefits of Regular Vehicle Maintenance

Material Engineering and Structural Design

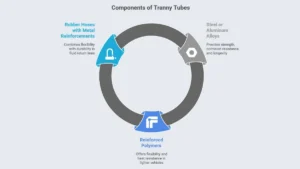

Tranny tubes should be able to withstand severe temperatures, vibrates, and chemicals. To this end, they are usually made of:

- Steel or Aluminum Alloys: These provide strength, corrosion resistance, and longevity.

- Reinforced Polymers: Used in lighter-weight vehicles, these offer flexibility and resistance to heat.

- Rubber Hoses with Metal Reinforcements: Found in fluid return lines, combining flexibility with durability.

Technological Advancements

With modern vehicles becoming increasingly computerized and efficient, tranny tubes are being engineered to support:

- Sensor Integration: Monitoring temperature and fluid flow in real-time.

- Smart Diagnostics: Alerting the driver or technician to pressure drops or fluid anomalies.

- Modular Design: Allowing quick replacement without dismantling the entire system.

These innovations ensure that even this small component keeps pace with the broader advancements in automotive engineering.

Tranny Tube vs. Related Automotive Fluid System Components

| Component | Primary Function | Material Composition | Location | Role in Transmission System |

| Tranny Tube | Transfers and monitors transmission fluid; houses dipstick | Steel, aluminum, reinforced polymer | From transmission to dipstick opening | Ensures fluid delivery, cooling, and shields from debris |

| Transmission Cooler Line | Circulating transmission fluid to and from the cooler | Steel tubing or rubber with metal braid | Connects transmission to radiator or cooler | Helps regulate transmission temperature |

| Transmission Dipstick | Measures fluid level and condition | Metal rod with plastic or rubber handle | Inserted through tranny tube into transmission | Allows monitoring of fluid volume and health |

| Radiator Hose | Transfers engine coolant to and from the radiator | Reinforced rubber or silicone | Between engine and radiator | Cools engine (not part of transmission system) |

| Hydraulic Line | Transports hydraulic fluid in heavy-duty systems | High-pressure steel or synthetic rubber | Various locations in hydraulic systems | Not specific to transmission, used in steering or brakes |

Final Thought

The tranny tube is an element in the vital health and efficiency of the transmission system of a vehicle and is often underestimated to ignore its existence. It contributes to a free performance and long life by ensuring the right flow of Fluid, cooling, and prevention of contamination. This is an especially small but important part that should be frequently checked and serviced to avoid expensive repairs and keep your automobile in top condition.

-

BIOGRAPHY9 months ago

BIOGRAPHY9 months agoBehind the Scenes with Sandra Orlow: An Exclusive Interview

-

HOME1 year ago

HOME1 year agoDiscovering Insights: A Deep Dive into the //vital-mag.net blog

-

HOME1 year ago

HOME1 year agoSifangds in Action: Real-Life Applications and Success Stories

-

BIOGRAPHY1 year ago

BIOGRAPHY1 year agoThe Woman Behind the Comedian: Meet Andrew Santino Wife