TECHNOLOGY

GT10C: The Powerful Upgrade from ALSTOM’s GT10B

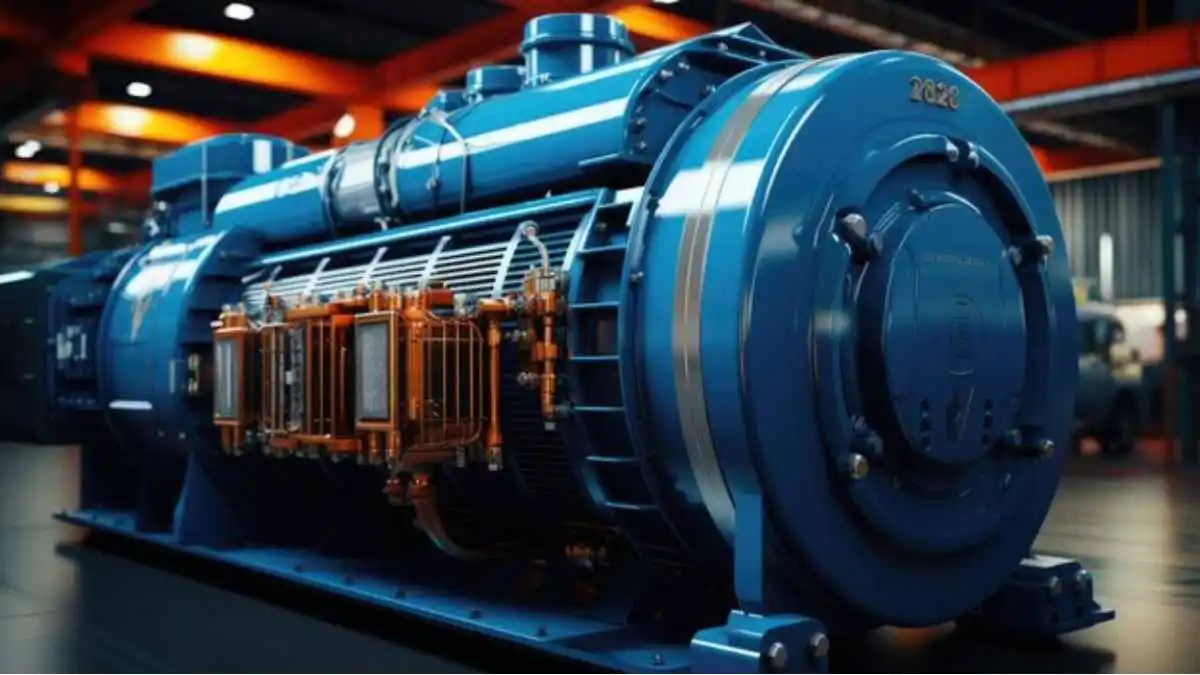

GT10C Gas Turbine is a 30 MW industrial gas turbine developed by ALSTOM Power as an upgraded model of the GT10B, which previously had a capacity of 25 MW. This advanced turbine is engineered to significantly enhance power output, reliability, and operational efficiency, making it a crucial energy source for various industrial applications. With rising global energy demands and the need for sustainable solutions, it provides industries with a dependable option to meet their energy needs while minimizing environmental impacts. ALSTOM’s commitment to innovation and efficiency is evident in this robust turbine design.

Significance of the GT10C in Industrial Applications

The GT10C holds significant importance in industrial applications due to its ability to provide reliable and efficient power. In sectors such as manufacturing, chemical processing, and energy production, consistent energy supply is critical for operational success. The turbine’s upgraded capacity allows it to support large-scale operations while ensuring that energy production is not compromised. Moreover, its adaptability to various fuels makes it suitable for diverse industrial settings. As industries strive for sustainability, its efficient performance helps reduce operational costs and enhances overall productivity, solidifying its role as a vital energy solution.

Key Features of the GT10C

- Increased Power Output: Provides 30 MW, surpassing the 25 MW capacity of its predecessor, the GT10B.

- Enhanced Efficiency: Optimized design for improved fuel consumption and operational performance in industrial applications.

- Advanced Control System: Features a state-of-the-art control system that ensures stability and efficiency under varying load conditions.

- Reliability and Durability: Engineered for consistent performance, enhancing reliability in demanding operational environments.

- Maintenance-Friendly Design: Simplifies servicing procedures, reducing downtime and boosting productivity through easier maintenance access.

Technical Specifications of the GT10C

The technical specifications of the GT10C highlight its capabilities as a leading industrial gas turbine. With a power output of 30 MW, it operates efficiently across a range of applications. The turbine features a thermal efficiency rating that meets or exceeds industry standards, optimizing fuel use and reducing emissions. Its compact design allows for easier integration into existing facilities, while the weight and dimensions are tailored for flexible installation options. Additionally, its performance metrics, such as load capacity and operational speed, ensure that it can handle varying demands without sacrificing reliability.

Design Improvements from the GT10B

The design improvements of the GT10C from the GT10B reflect ALSTOM’s commitment to innovation and efficiency. Significant changes include advancements in turbine blade technology, which enhance aerodynamics and heat resistance, leading to better performance under high-load conditions. The cooling systems have also been upgraded to ensure optimal operation in diverse environments, reducing the risk of overheating. These design enhancements not only contribute to the turbine’s reliability but also extend its operational lifespan. The overall engineering approach emphasizes robustness while maintaining a lightweight structure, facilitating easier installation and maintenance.

Benefits of Upgrading to the GT10C

- Enhanced Efficiency: Significant reductions in fuel consumption lead to lower operational costs, positively impacting the bottom line.

- Cost Savings: Improved efficiency translates to decreased energy expenses, enhancing overall profitability for industries.

- Environmental Compliance: The turbine’s superior environmental performance helps industries meet stringent emissions regulations, promoting sustainable practices.

- Fuel Flexibility: Capable of accepting various fuel types, including natural gas and biogas, offering greater operational versatility.

- Reliable Energy Source: Ensures industries can depend on a powerful and efficient energy solution to meet growing energy demands responsibly.

Applications of the GT10C

The GT10C gas turbine is widely applicable across various industrial sectors, showcasing its versatility and reliability. In the manufacturing industry, it serves as a critical power source for heavy machinery and production lines, ensuring uninterrupted operations. In the energy sector, it can be deployed in power plants to provide stable electricity generation, contributing to grid stability. Additionally, the turbine finds applications in the petrochemical industry, where its ability to use different fuels makes it ideal for processing operations. Case studies highlight successful installations where it has significantly improved energy efficiency and operational output.

Comparison with Competitor Turbines

When compared to competitor turbines in the same capacity range, the GT10C stands out due to its unique blend of efficiency and performance. Many competing models may offer similar power outputs; however, its advanced control systems and design innovations often result in superior operational reliability. Additionally, the turbine’s adaptability to various fuel types provides it with a competitive edge, particularly as industries shift toward more sustainable energy sources. Strengths such as lower emissions and reduced maintenance requirements make it an attractive choice for companies looking to enhance their energy strategies without compromising performance.

Operational Efficiency and Reliability

Operational efficiency and reliability are paramount in industrial energy applications, and the GT10C excels in both areas. The turbine’s design incorporates advanced monitoring and control technologies that optimize performance, ensuring it operates efficiently across a range of load conditions. This adaptability minimizes the likelihood of downtime, allowing industries to maintain consistent production levels. Regular maintenance schedules are simplified thanks to the turbine’s design, which reduces the need for extensive service interruptions. Its track record of reliability enhances its reputation as a dependable energy solution, allowing businesses to operate with confidence.

Environmental Impact of the GT10C

The environmental impact of the GT10C is a critical consideration in today’s energy landscape. The turbine is designed to meet stringent emissions regulations, significantly reducing greenhouse gas outputs compared to older models. Its high thermal efficiency means that less fuel is consumed for the same energy output, leading to lower carbon emissions. Additionally, its flexibility in fuel usage allows it to incorporate renewable energy sources, further diminishing its environmental footprint. By investing it, industries can improve their sustainability efforts while fulfilling energy demands, contributing to a greener future.

Cost Analysis of the GT10C

Conducting a cost analysis of it reveals its potential for long-term savings and operational efficiency. While the initial investment may be higher than older models, the turbine’s increased efficiency and reduced fuel consumption lead to substantial savings over time. The total cost of ownership is further mitigated by lower maintenance requirements and enhanced reliability, resulting in fewer operational disruptions. Additionally, as industries increasingly prioritize sustainability, the GT10C’s reduced emissions can help avoid potential regulatory costs. Overall, the economic benefits of adopting it far outweigh the initial investment, making it a wise choice for industrial applications.

Installation and Integration Process of GT10C

The installation and integration process of the GT10C turbine is designed to be efficient and straightforward. The turbine’s compact design allows for flexible installation options, which can be tailored to fit existing facilities. Installation typically involves site preparation, alignment, and connection to existing systems, all of which are supported by ALSTOM’s experienced teams. The integration process includes ensuring compatibility with control systems and other equipment. Proper installation is crucial for optimizing performance, and ALSTOM provides comprehensive support throughout the process, ensuring that the turbine operates at its best from day one.

Customer Support and Maintenance Services

ALSTOM’s customer support and maintenance services for the GT10C are integral to ensuring long-term operational success. The company offers a range of services, including regular maintenance checks, troubleshooting, and performance assessments. Their trained technicians are equipped to address any issues promptly, minimizing downtime and maintaining productivity. Additionally, ALSTOM provides training programs for personnel to ensure that operators are well-versed in turbine operation and maintenance best practices. This commitment to customer support not only enhances the longevity of it but also fosters strong partnerships with clients, contributing to their overall success.

-

BIOGRAPHY9 months ago

BIOGRAPHY9 months agoBehind the Scenes with Sandra Orlow: An Exclusive Interview

-

HOME1 year ago

HOME1 year agoDiscovering Insights: A Deep Dive into the //vital-mag.net blog

-

HOME1 year ago

HOME1 year agoSifangds in Action: Real-Life Applications and Success Stories

-

BIOGRAPHY1 year ago

BIOGRAPHY1 year agoThe Woman Behind the Comedian: Meet Andrew Santino Wife