TIPS

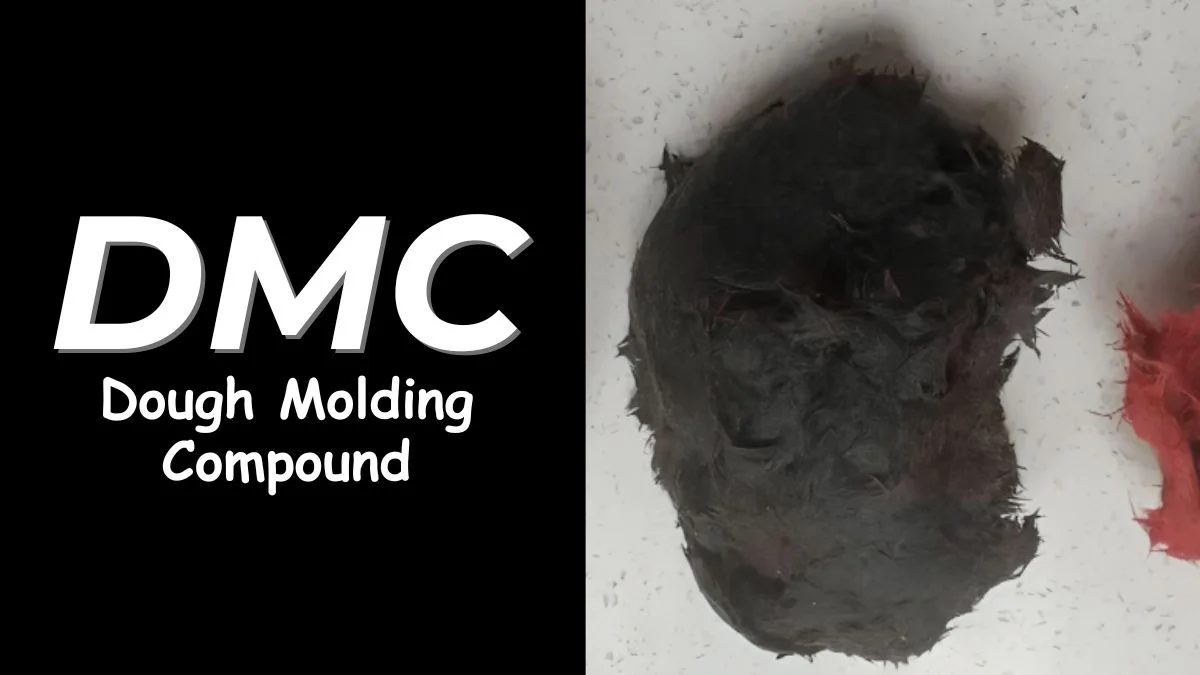

Dough molding compound: The Strong, Durable Thermoset Material

Dough molding compound (DMC) is a hot setting matrix established as a resin-based thermosetting plastic-reinforced material with high mechanical properties. DMC is a product that has unsaturated polyester resin, fillers, glass fiber reinforcements, and additives; it is used in various industries which require high-performance materials. Apart from possessing superior electrical insulation and heat, chemical, and moisture-resistant material, DMC is suitable for automotive parts, electric insulation in electrical and electronics appliances, and construction materials.

How Dough Molding Compound Works

Dough Molding Compound gets its title from the characteristic giving it the therapeutic asset of a material that hardens when warmed as opposed to softening, a phenomenon typical of thermosetting materials, and on which the whole science of the Dough Molding Compound is built. In molding DMC, which can reach high temperatures, a chemical change takes place that solidifies or permanently fixes the setting of the resin. This curing process alters DMC from a highly pliable dough-like material to a rigid solid with excellent fire, moisture, and chemical resistance. DMC comprises glass fibers which give it reinforcement properties that also give it tensile strength and structure. Thus, the interaction of unsaturated polyester resin and additives allows DMC to address the requirement of shapes to offer them high-strength characteristics necessary for precise and high-stress applications.

Manufacturing Process of DMC

The DMC manufacturing process involves the blending of unsaturated polyester resin with glass fiber fillers and additives. It is kneaded to a pastry-like paste, which can easily be modeled in various forms. This “dough” is then compression molded or injection molded into the shape that it is needed in. A common characteristic of compression molding is that it is applied to large and massive strong and massive parts, whereas, injection molding is applicable for small precision parts. In molding, heat and pressure are used to further cure the compound to take a rigid or hard structure, which is more durable than the original. This controlled process helps the manufacturers achieve very complex and detailed designs with the same parameters reproduced at every step.

Types of DMC Molding: Compression and Injection Molding

There are two primary molding methods used for shaping DMC:

Compression Molding

This method involves placing Dough Molding Compound into a heated mold cavity and applying pressure until it takes the desired shape. It is ideal for larger parts that require structural integrity. The process allows for the creation of durable, high-strength components with a relatively simple mold design.

Injection Molding

In this method, molten Dough Molding Compound is injected into molds under high pressure, offering precision and speed. It is perfect for producing small, intricate components that require detailed designs. Injection molding allows for the efficient production of complex parts with tight tolerances and faster cycle times.

DMC vs. Other Thermoset Composites

DMC is an exceptional thermoset composite compared to other composites available in the market. Other similar materials include Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC); however, due to the nature of the DMC, it is firmer in dough and is better suited for intricate shapes with fine detail work. DMC is comparatively strong and quite flexible and is also an insulator, which cannot be said of any rigid material with certainty. Also, it experiences lower shrinkage levels after molding which makes DMC ideal for applications that require higher accuracy on dimension. The current formula of DMC can be adjusted for certain applications, an advantage that gives the product more flexibility in usage than many other competing thermoset composites.

Applications of DMC in the Automotive Industry

Dough Molding Compound is used intensively in the automotive industry due to its features, such as durability and accuracy. Several automotive components are produced using DMC, these may include battery casing, distributor cap, and some parts under the bonnet. Since DMC possesses good heat resisting and tensile strength it is therefore suitable for use in parts that are exposed to high temperature and mechanical loading. The fact that it can maintain the sharpness of the shapes and continue to resist unfavorable conditions guarantees its long-lasting working period. Moreover, the electrical insulating property of Dough Molding Compound is well-suited in automotive applications, especially electronic parts, to meet the demand of the automotive industry for materials with required electrical insulation and mechanical strength.

Properties That Make DMC Stand Out

- Strength and Durability: Dough Molding Compound offers exceptional strength and long-lasting durability, making it reliable for demanding environments.

- Electrical Insulation: It provides outstanding electrical insulation, making it an ideal material for electronic components and electrical systems.

- Resistance to Heat, Moisture, and Chemicals: Dough Molding Compound performs reliably in harsh conditions, with resistance to heat, moisture, and chemicals, ensuring its stability over time.

- Rigidity: The material’s rigidity ensures that components maintain their shape and structural integrity even under stress or over extended use.

- Versatility in Molding: DMC’s flexibility in molding allows for the creation of complex, high-precision designs, making it suitable for a wide range of applications

DMC in Electrical Industry: Insulation and Safety

DMC possesses tremendous insulation and heat-shield capabilities in any electrical context, which are fundamental. Dough Molding Compound is used by electrical insulators, switch components, and circuit breakers due to its electrical non-conductivity and heat resistance from a content point of, the material’s stiffness and minimal retraction guarantee that components do not deform when applying pressure on them. In addition, the usage of DMC in products as an electrical insulating material makes appliances safer in terms of electrical fires. Hence, DMC is in high demand from manufacturers who are searching for excellent electrical equipment insulators that are equally protective, light in weight, and resistant to heat.

Construction of Dough Molding Compound

- Durability in Harsh Environments: DMC’s robustness makes it ideal for construction applications that require materials able to withstand extreme conditions.

- Resistance to Heat, Moisture, and Chemicals: DMC’s resistance to environmental factors such as heat, moisture, and chemicals ensures long-lasting performance in construction.

- Lightweight yet Strong: Its lightweight nature makes it easy to handle and install, while its strength ensures structural integrity.

- Precise Shapes for Custom Designs: Dough Molding Compound can hold intricate shapes, allowing for highly customized designs, meeting the demands of modern architectural aesthetics.

- Enhanced Structural Integrity: DMC contributes to the overall strength and durability of construction materials, making it a reliable choice for critical components like wall claddings, piping, and structural panels.

The Process of Designing with Dough Molding Compound

The use of DMC in designing paves the way for the creation of complex shapes of the highest accuracy. That is why the material has high molding capabilities to make different components with small deviations and intricate inserts. Part-to-part molding techniques such as compression and injection molding both allow shaft designs to be fine and detailed, thus meeting aesthetic and functional objectives. Plasticity after the curing process is also a strength of DMC because it maintains the stability of structures and forms of designs applicable in detailed industries. Dough Molding Compound has a versatile design structure as its flexibility serves as the perfect tool for manufacturers seeking to produce unique parts with precise characteristics.

Sustainability and Recycling Aspects of Dough Molding Compound

Despite the material being durable and reliable the issue of sustainability in its attainment as well as disposal is topical. At the moment, materials such as Dough Molding Compound are difficult to recycle due to the inability to remelt them after they have cured. But, recently coming technologies in the field of recycling are making it possible to recycle some of these thermoset composites. Improvement has been made in the sustainability of this product through modification of its formulation and, more so, in the manner used in post-consumer consumption. Increased industry demand for sustainable materials might be guided by studies in biodegradable additives as well as environmentally friendly methods of production, thus pointing to more sustainable ways of producing DMC.

Looking for more? Explore our blog for valuable tips and the latest updates!

-

BIOGRAPHY7 months ago

BIOGRAPHY7 months agoBehind the Scenes with Sandra Orlow: An Exclusive Interview

-

HOME1 year ago

HOME1 year agoDiscovering Insights: A Deep Dive into the //vital-mag.net blog

-

HOME1 year ago

HOME1 year agoSifangds in Action: Real-Life Applications and Success Stories

-

BIOGRAPHY1 year ago

BIOGRAPHY1 year agoThe Woman Behind the Comedian: Meet Andrew Santino Wife